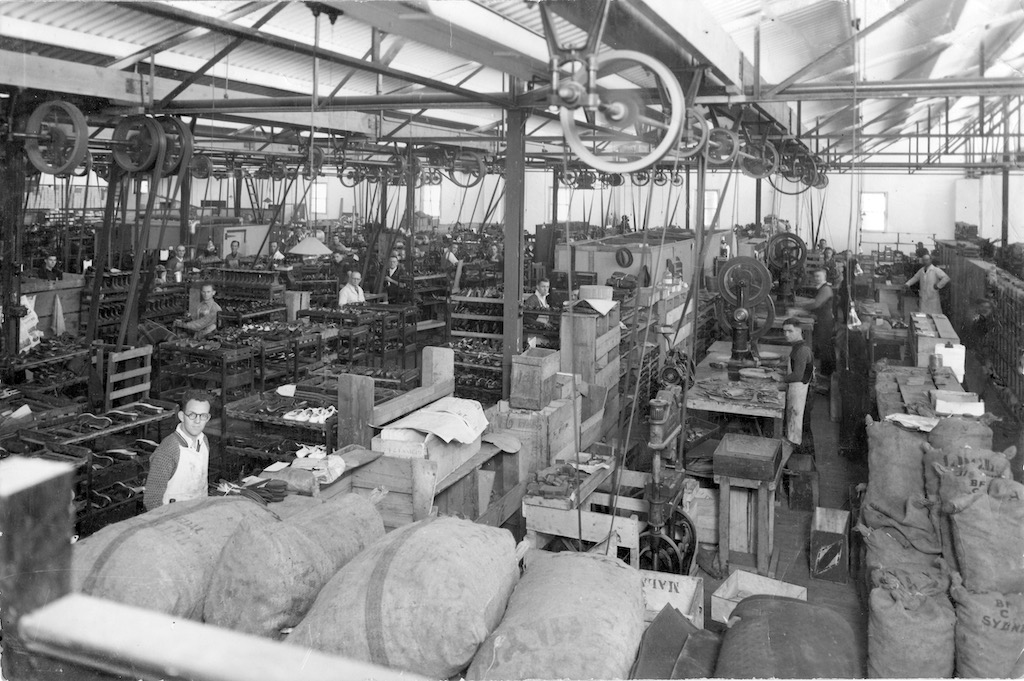

Look at the hundreds of pairs of shoes on the left-hand side of this photograph inside Baxter’s boot factory in 1930, and the number of employees. Photo: History Goulburn.

Long-term Goulburn residents have an inherent interest in the fortunes of new enterprises like Tribe Breweries, and the ongoing success of Southern Meats, because like many Australians we yearn for the days when we were good at manufacturing.

Goulburn historians Linda Cooper and Roger Bayley have records covering the extraordinary celebrations of the city’s booming industrial sector stemming from sheep, cattle and dairy farms, fruit growing and quarrying of slate, marble and sandstone.

By 1930 the City Council had lowered the price of power to decrease production costs as boot and brick makers and textile mills ramped up their output.

“This means that Goulburn is supplying power at less cost than any other place in NSW with the exception of Newcastle, which has its coal at its door,” mayor Alderman A Wheatley said when opening Made in Goulburn Week at the Empire Theatre in October 1930.

Baxter’s Boot Factory and Gulson’s Brick and Pottery were prominent, and cabinetmaker F. R. Elton, who displayed a beautiful bedroom suite manufactured in Goulburn of figured American sycamore with inlays of kingwood burr-walnut, green heart, and various other woods.

Conolly’s Flour Mill products included “Cream of Wheat’’ which could be used as a light breakfast food, while the mayor singled out Amalgamated Textiles Ltd, (aka Goulburn Woollen Mills), because he was wearing a suit the material of which was made at the mills.

Of course, the city’s industrial sector had swung into action much earlier. “We grow, we mine, we manufacture,’’ a large sign boasted in a procession down Auburn Street marking the city’s first centenary in October 1920.

Jam manufacturers, flour millers, tinsmiths and embroiders and engravers often shared the limelight with the city’s two rival bootmakers, Gillespie and Company and Baxter and Company.

In that famous 1920 procession Gillespie’s Buffalo Tannery and Factory used two lorries to demonstrate its wares, “from the beast to the hide”.

The Daily Telegraph in 1922 said Goulburn was keen on being self-contained, and was now able to shoe, clothe and feed itself and was about to go a step further and wash itself. Southland Manufacturing Company was joining the drive to decentralising industry by increasing its soap production.

Earlier in 1909, then prime minister of Australia Andrew Fisher opened Goulburn’s inaugural industrial exhibition for manufacturers and trades, assembled on the ground floor of Rogers Great Arcade in Auburn Street. The upstairs floor was set aside for the arts and related fields.

Thousands of people came to see jam manufacturers, a tinsmith and building and timber merchants G. Lansdowne and J. Cody who had outstanding displays of timber and joinery, mantelpieces, overmantels, doors, stoves, gas fittings and glassware.

Hunt’s Prize Medal Baking Powder shared the hall with the Wunderlick Metal Ceiling Co., potatoes grown at Laggan and Laggan Flour Mill’s White Pearl Flour. Steele and Co. displayed their cordials and aerated water, while Mr A. Overall showed off his Goulburn-made confectionery.

John Cody and Sons were prominent in Auburn Street, Goulburn in the 1930s. The builders were strong supporters of Goulburn industry exhibitions. Photo: History Goulburn.

Over the years, Goulburn’s two boot makers overcame workshop accidents, floods and fires to expand their businesses. A fierce fire gutted Gillespie’s two-storey factory in Auburn Street, destroying plant and machinery and more than 500 pairs of military boots under contract for the armed forces, according to an extract in Stephen Tazewell’s Grand Goulburn.

The following year Gillespie’s came back with 70 employees and a new factory further along Auburn Street which could turn out 400 boots a day.

Baxter’s tannery also incurred big losses in a fire in 1938 and years later installed a sprinkler system to avoid another disaster.

In April 1941 Baxter and Company’s boot factory staff were under pressure to fulfil a special war order for 25,000 pairs of military boots, its biggest ever contract.

Over the years other manufacturers and wool processors came to Goulburn, flourished and like manufacturing around the country, subsided.

Now the shelves of big box stores like Bunnings are stocked with goods made in China. They’re probably cheaper and more efficient than what Goulburn turned out in its early years of development, but will never match the characteristics of those locally-made products that instilled so much hope and pride for the future of Australia.