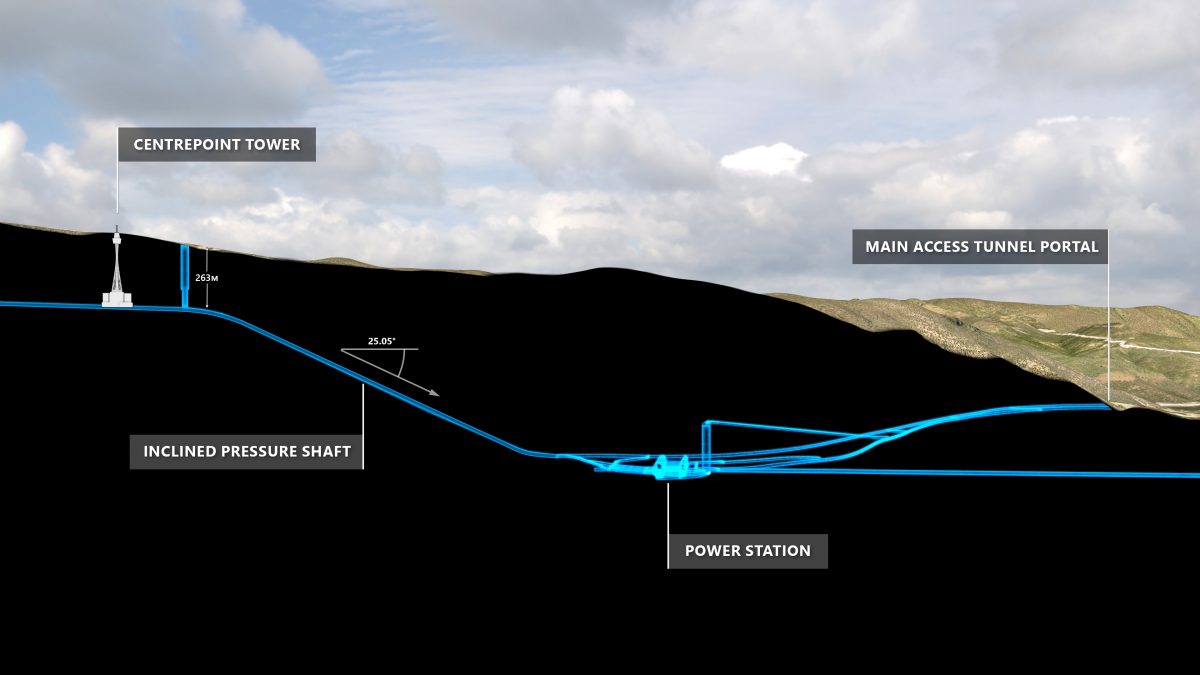

An illustration showing the inclined pressure shaft at Snowy 2.0 project, Lobs Hole. Image: Snowy Hydro.

Amid controversy about construction delays and a “paused” tunnel boring machine (TBM), the Snowy 2.0 pumped-hydro mega project has achieved another important milestone, with a second tunnel excavation completed at Lobs Hole in the Snowy Mountains.

The 2.93-kilometre emergency, cable and ventilation tunnel (ECVT) has been excavated and fully lined with 13,140 locally made concrete segments by TBM Kirsten.

This achievement follows the excavation of the adjacent main access tunnel (MAT), which was completed in October 2022.

Snowy Hydro CEO Dennis Barnes said Snowy 2.0 was continuing to make solid progress, with about six kilometres of tunnelling by TBMs completed, and drill and blast excavation of the power station cavern about to start.

“We are extremely pleased the ECVT excavation has been completed and the whole project team is excited to be moving into the next critical phase of construction,” Mr Barnes said.

”Our huge power station cavern will be located about 800 metres underground and will be one of the largest and deepest in the world. We are also using drill and blast methods to construct cross-passages linking the ECVT with the MAT.

“Meanwhile, TBM Kirsten, which is setting a global standard in TBM technology, is being modified to carry out another very specific task – to excavate the inclined pressure shaft and line it with specially designed and locally manufactured concrete segments.

“The shaft is 1.45 km long and excavating a segment-lined tunnel of this length at a very steep 47 per cent incline using an 11m-diameter TBM is without precedent internationally.”

Modifications to Kirsten include altering the levels of the TBM’s tanks and mechanical equipment so they remain horizontal when travelling up the incline, and converting the walkways into steps and ladderways.

Also being installed is a screw conveyor to take excavated rock from the cutter head to a sandwich conveyor system with face-to-face rubber belts that help constrain the crushed rock so that it can be transported down the steep slope without spillage.

Additional plant and equipment will also be installed in the ECVT tunnel to support the excavation activities, including: an overhead crane, a conveyor transfer station, a monorail manrider for personnel access, and a rack-and-pinion mechanism for plant access to the TBM.

There is currently a project workforce of more than 2700 across four major worksites building Snowy 2.0, a critically important, pumped-hydro expansion of the Snowy Scheme that will help underpin Australia’s transition to renewables.

ECVT fast facts:

- 2.93km in length

- 10m internal diameter

- Lined with 1460 concrete rings with nine segments per ring installed by TBM Kirsten

- Precast segments are manufactured in Cooma

- ECVT has five cross-passages linking it to the adjacent main access tunnel

- Provides secondary access with clean air to the power station complex and will be used permanently for ventilation and high-voltage cables, and intermittently for general access and maintenance.